Industrial AI: Revolutionizing the Manufacturing Landscape

In recent years, Industrial AI has emerged as a transformative force in the manufacturing sector. By integrating artificial intelligence technologies into industrial processes, companies are achieving unprecedented levels of efficiency, precision, and innovation.

What is Industrial AI?

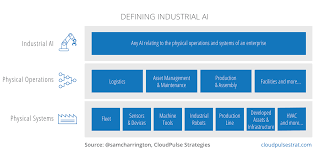

Industrial AI refers to the application of artificial intelligence in industrial settings. This includes using machine learning algorithms, computer vision, natural language processing, and robotics to optimize manufacturing processes. The goal is to enhance productivity, reduce costs, and improve product quality.

Key Applications of Industrial AI

- Predictive Maintenance: By analyzing data from sensors embedded in machinery, AI systems can predict equipment failures before they occur. This minimizes downtime and reduces maintenance costs.

- Quality Control: Computer vision systems powered by AI can inspect products for defects with greater accuracy than human inspectors. This ensures higher quality standards and reduces waste.

- Supply Chain Optimization: AI algorithms analyze supply chain data to forecast demand more accurately and optimize inventory levels, leading to cost savings and improved customer satisfaction.

- Robotics Automation: Intelligent robots equipped with AI can perform complex tasks with precision and adaptability, enhancing production capabilities.

The Benefits of Industrial AI

The integration of AI into industrial processes offers numerous benefits:

- Increased Efficiency: Automation reduces manual intervention and accelerates production cycles.

- Cost Reduction: Predictive maintenance and optimized resource management lead to significant cost savings over time.

- Enhanced Flexibility: AI-driven systems can quickly adapt to changes in production requirements or market demands.

- Sustainability: By optimizing resource usage and reducing waste, Industrial AI contributes to more sustainable manufacturing practices.

The Future of Industrial AI

The future of Industrial AI looks promising as advancements continue at a rapid pace. As machine learning models become more sophisticated and data collection methods improve, the potential applications for Industrial AI will expand further. We can expect smarter factories that are capable of self-optimization, leading to even greater efficiencies across industries.

The adoption of Industrial AI is not without challenges. Concerns about data security, workforce displacement due to automation, and the need for upskilling employees must be addressed. However, with careful planning and strategic implementation, these challenges can be managed effectively.

Conclusion

Industrial AI is set to revolutionize the manufacturing landscape by driving innovation and efficiency across all stages of production. As technology continues to evolve, businesses that embrace these advancements will be well-positioned to thrive in an increasingly competitive market environment.

The journey towards fully realizing the potential of Industrial AI has just begun. Companies that invest in this technology today will reap substantial benefits tomorrow—ushering in a new era of smart manufacturing that is both efficient and sustainable.

Understanding Industrial AI: Key Questions and Insights

- What is industrialized AI?

- What is industry AI?

- What is an example of AI in industry?

- Who is leading the AI industry?

- What are the 4 types of AI?

What is industrialized AI?

Industrialized AI refers to the systematic integration and deployment of artificial intelligence technologies across industrial operations to enhance efficiency, productivity, and innovation. Unlike experimental or isolated AI applications, industrialized AI involves scaling AI solutions to be robust, reliable, and adaptable to various industrial contexts. This includes automating complex processes, improving predictive maintenance through data analytics, optimizing supply chain logistics, and enhancing quality control with computer vision systems. By embedding AI into the core of industrial workflows, businesses can achieve significant cost reductions, improve product quality, and respond more swiftly to market demands. The ultimate goal of industrialized AI is to create smart factories that are capable of self-optimization and continuous improvement.

What is industry AI?

Industry AI, often referred to as Industrial AI, involves the application of artificial intelligence technologies specifically within industrial sectors such as manufacturing, logistics, and energy. It encompasses the use of machine learning algorithms, computer vision, natural language processing, and robotics to optimize various industrial processes. The primary aim of Industry AI is to enhance operational efficiency, improve product quality, reduce costs, and drive innovation by enabling machines and systems to perform tasks that traditionally required human intelligence. By analyzing vast amounts of data generated in industrial environments, AI solutions can predict maintenance needs, optimize supply chains, automate quality control processes, and facilitate smarter decision-making. This integration of AI into industry not only boosts productivity but also fosters more sustainable and adaptable operations.

What is an example of AI in industry?

One prominent example of AI in the industry is the use of predictive maintenance in manufacturing plants. By deploying AI algorithms to analyze data collected from sensors on machinery, companies can predict equipment failures before they occur. This approach allows for timely maintenance, reducing unexpected downtime and minimizing repair costs. For instance, a manufacturing facility might use AI-driven systems to monitor vibrations, temperature, and other operational parameters of its machines. When the system detects anomalies that suggest potential malfunctions, it alerts maintenance teams to take preventive action. This not only enhances operational efficiency but also extends the lifespan of equipment, ultimately leading to significant cost savings and improved productivity.

Who is leading the AI industry?

Several key players are leading the AI industry, particularly in the realm of industrial applications. Companies like IBM, Siemens, and General Electric are at the forefront, leveraging their expertise in industrial technologies to integrate AI solutions into manufacturing and production processes. IBM’s Watson platform is renowned for its AI capabilities across various sectors, while Siemens is known for its advancements in automation and smart factory solutions. General Electric has been instrumental in using AI for predictive maintenance and optimizing industrial operations. Additionally, tech giants like Google, Microsoft, and Amazon are also making significant strides by providing cloud-based AI services that support industrial applications. These companies are investing heavily in research and development to push the boundaries of what AI can achieve in industrial settings.

What are the 4 types of AI?

When discussing the types of AI, it is important to understand that these categories reflect the varying levels of complexity and capability in artificial intelligence systems. The four primary types of AI are Reactive Machines, Limited Memory, Theory of Mind, and Self-Aware AI. Reactive Machines are the most basic form, capable only of reacting to current inputs without the ability to form memories or use past experiences. Limited Memory AI systems can utilize past data to inform future decisions, which is commonly seen in technologies like self-driving cars. Theory of Mind represents a more advanced stage where AI can understand emotions and intentions, allowing for more sophisticated interactions with humans. Finally, Self-Aware AI is a theoretical concept where machines possess self-consciousness and awareness similar to human beings; however, this level has not yet been achieved in practice. Each type represents a step forward in the development and potential applications of AI technology within various industries, including manufacturing and beyond.